FLUID MECHANICS 1 0901.341

Fall 1998

Chapter Review Guide for Fluid Mechanics, by Franzini et al. You can

use this page to test your understanding of each chapter. The focus is

identifying important equations and major concepts. However, don't use

this as an excuse for not reading the book! If you find any mistakes (typos,

etc.), let Dr. E. know as soon as possible!!

Back to Fluid Mechanics' home page

Table of Contents

Back to Table of Contents

Chapter 1

Approach to problem solving

Systems of units (BG and SI)

Dimensions (F, M, L, T)

Back to Table of Contents

Chapter 2

Concepts

Ideal fluid

Real fluid

Surface tension and capillarity

Vapor pressure

Variables

Density, r

Specific weight, g

Specific volume, u

Bulk modulus (also know as volume modulus), Eu

Specific gravity, s

viscosity (absolute and kinematic), m and

n

surface tension, s

wetting angle, q

Relationships

g = rg

u = 1 / r

Eu = -u

dp/du

Du / u y

- DP / Eu

s = r/rref

= g/gref

(where the reference substance is often water)

pu = RT

t= F/A = m U/Y

= m du/dy

n = m / r

h = (2s cos q)/

gr

Back to Table of Contents

Chapter 3

Concepts

Pressure at a point in a fluid is the same in all directions

Pressure varies as a function of depth and specific weight in fluids

Barometer

Pressure measurement

Bourdon gage, Pressure Transducer, Piezometer Column, Simple

and Differential Manometer

Forces and locations of forces on submerged plane and curved areas

Buoyancy and Stability

Fluid masses subjected to acceleration

Variables

Pressure head, h

Atmospheric, absolute and gage pressures, patm, pabs

and pgage

Centroid of area, hc, yc

Centroid of Pressure, hp, yp

Moment of Inertia (about an arbitrary axis and about a centroidal axis),

IO and Ic

Weight Force, W

Buoyancy force, FB

System subscript, S

Control volume subscript, CV

Relationships

DP/dz = - g

p = gh

h = p / g

pabs = patm + pgage

Be able to derive pressure relationships for piezometers and manometers

F = xp dA = ghcA

yp = IO / ycA = yc + IC

/ ycA

W = specific weight of object times its volume

FB = specific weight of water times volume of water displaced

by object

W = FB (for an object that is not rising

or falling in a fluid)

Back to Table of Contents

Chapter 4

Concepts

Ideal vs. real

Incompressible vs. compressible

Steady

Uniform

Laminar

Turbulent

Path line

Streamline

Flowrate (volume, mass, weight)

Mean velocity

System (S) and control volume (CV)

Continuity

Flow net, streamlines and equipotential lines

Velocity and acceleration in steady flow

Velocity and acceleration in unsteady flow

Variables

Volumetric flowrate, Q

Mass flowrate, m with dot on top (I'll just use m' here)

Weight flowrate, G

Velocity, V

Acceleration, a

Steady flow subscript, st

Bolding indicates a vector

Relationships

Q = VA

V = Q / A

m' = rQ (for constant

density flow)

G = gQ (for constant density

flow)

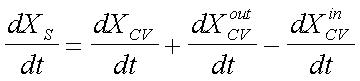

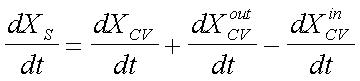

System - Control Volume Equation:

In words: change of X in the moving system equals change of

X within the control volume plus the flow of X out of the control volume

minus flow of X into the control volume.

A1V1 = A2V2 (incompressible

flow, steady flow)

r1A1V1

= r2A2V2 (steady

flow)

g1A1V1

= g2A2V2 (constant

gravity, steady flow)

ast = V cV/cs

(steady flow, s is direction tangent to streamline)

a = V CV/Cs

+ CV/ct

(unsteady flow, s is direction tangent to streamline)

Back to Table of Contents

Chapter 5

Concepts

Energy (kinetic, potential, pressure, internal,...)

General energy equation

Head (pressure, elevation, velocity, total, piezometric, static,...)

Power

Efficiency

Cavitation

Energy grade line

Hydraulic grade line

Head loss

Variables

a = Kinetic energy correction factor

I = internal energy per unit weight of fluid

p/g = flow work, pressure acting on flow

hM = shaft work, put into fluid by machine per unit weight

of fluid

QH = energy put into fluid by external heat source per unit

weight of fluid

hl = head loss

Relationships

Energy = Force time distance

Energy/unit weight has units of length

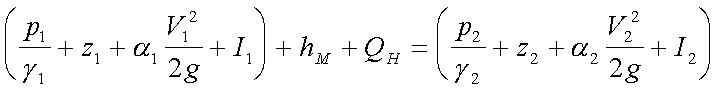

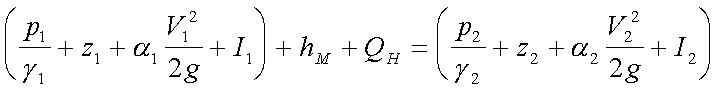

General energy equation (5.8):

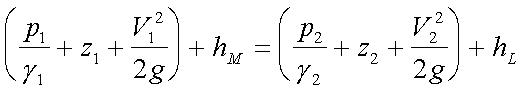

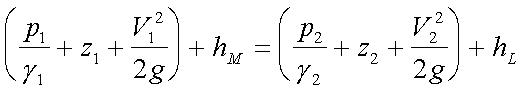

Bernoulli's equation (5.13):

hl = (I2 - I1) - QH

Power = hgQ = energy per time

Efficiency = power output / power input

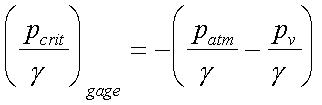

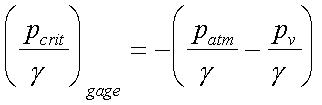

Cavitation (5.36):

Back to Table of Contents

Chapter 6

Concepts

Impulse-momentum principle

Navier Stokes equations

Force exerted on pressure conduits

Force exerted on stationary and moving vanes or blades

Absolute and relative velocities

Jets and Jet Propulsion

Pumps and Turbines, water

Head equivalent of hM

Reaction and rotating jets

Fans and Propellers, gases

Variables

Q' = rate of fluid striking a moving body, function of relative

velocities between water and body

V = absolute velocity of water

u = relative velocity of water (to some

moving body)

u = absolute velocity of moving body

Relationships

nF =

d(mV)s / dt

NF = rQ

(DV), for steady flow and stationary bodies

NF = rQ'

(Du), for steady flow and a single moving

vane (only a portion of fluid momentum is transfered)

NF = rQ

(Du), for steady flow and a series of moving

vanes (all fluid momentum is transfered)

hM = (u1 V1 COs a1

- u2 V2 COs a2)

/ g

Back to Table of Contents

Chapter 7

Concepts

Simlitude and Similarity

Reynolds Number

Froude Number

Mach Number

Weber Number

Scale Ratios

Dimensional Analysis and the Pi Theorem

Variables

Subscripts: p = prototype, m = model

Scale ratio, Lr

Velocity ratio, Vr

Force ratio, Fr

Reynolds number, R

Froude Number, F

Mach Number, M

c = sonic velocity in medium in question

Weber Number, W

s = surface tension

Relationships

R = LVr/m

F = V (gL)-0.5

M = V / c

W = V (s/rL)-0.5

Back to Table of Contents

Chapter 8a (sections 1 - 16)

Concepts

Laminar and Turbulent Flow

Critical Reynolds number

Laminar Flow, R <

2000

Friction in circular conduits

Friction factor

Pipe Roughness (hydraulically smooth, transitionally rough, fully rough)

Moody Diagram

Pipe flow Problems (head-loss, discharge, and sizing problems)

Solution of pipe flow problems using the Moody Chart

Solution of pipe flow problems using explicit equations

Empirical equations for pipe flow

Variables

Reynolds number, R

Hydraulic radius, Rh

Cross-section area of flowing fluid, A

Wetted Perimeter, P

Friction factor, f

Equivalent height of roughness projections, e

relative roughness, e/D

Energy Gradient, S (= hL / L, where L = length

of pipe)

roughness coefficients, CHW and n

Relationships

Rh = A / P

hl = f (L/D) (V2/2g)

f = 64/R, for laminar flow in circular pipes

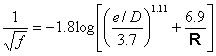

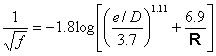

, for turbulent flow

, for turbulent flow

Various derived and "fitted" equations, see especially pages 289-291.

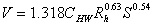

, BG units, formula is not unit-consistent,

limited applicability

, BG units, formula is not unit-consistent,

limited applicability

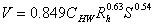

, SI units, formula is not unit-consistent,

limited applicability

, SI units, formula is not unit-consistent,

limited applicability

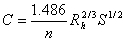

, BG units, formula is not unit-consistent,

limited applicability

, BG units, formula is not unit-consistent,

limited applicability

, SI units, formula is not unit-consistent,

limited applicability

, SI units, formula is not unit-consistent,

limited applicability

Solutions

Type 1: solved directly. Type 2, and 3 problems:

solved iteratively using Moody's diagram, iteratively using equations,

or solved using equation solvers, see pages 294-302.

Empirical equations, see page 304-305.

Back to Table of Contents

Chapter 8b (sections 17 - 28)

Concepts

Minor Losses

When to include minor losses

When a fitting creates a major loss (such as a valve that is

almost closed)

For short pipe lengths (a good rule of thumb is to include minor losses

if the pipe length is < 1000 D)

Solution of various pipe problems

Variables

loss coefficient, k

equivalent length, L/D or N (multiply by pipe diameter, D, to estimate

equivalent length of straight pipe that would give same head loss as source

of minor loss)

Relationships, minor losses

Entrances: h'e = ke

V2/2g, where ke ranges ~0 to ~ 0.8, see

page 309.

Submerged discharges: h'd = V2/2g,

see page 310.

Contractions: h'c = kc

V2/2g, where kc is a function of D2/D1,

where D2 = diameter after contraction, D1

= diameter before contraction, kc ranges from 0 to

0.5, see page 312.

Expansions, sudden: h'x = (V1

- V2)2/2g, where V2

= velocity after contraction, V1 = velocity before

expansion

Expansions, gradual: h' = k' (V1

- V2)2/2g, where V2

= velocity after contraction, V1 = velocity before

expansion, and k' is a function of cone angle, see page 316.

Pipe fittings: h = k V2/2g, where k depends on the

fitting, see page 317. Alternatively, one can use the equivalent

length concept (L/D from Table 8.3 times the pipe diameter). Add

the equivalent length of the fitting to the pipe length. This ensures

that the head loss caused by the fitting is taken into account, but as

pipe friction.

Bends: hb = kb

V2/2g, where kb is a function of relative

roughness and the ratio of the bend radius to the pipe diameter, see page

320.

Solutions, of specific types of pipe problems

Single-pipe flow with minor losses: Total head

loss is sum of pipe friction loss and minor loss, see page 321.

Pipeline with pump or turbine: Total head provided by

a pump or supplied to a turbine is a function of energy (change in elevation

and velocity, usually) and the pipe friction and minor losses, see page

327. Minor losses are often ignored.

Branching pipes: Need to use continuity and energy equations,

see page 331. Minor losses and even velocity heads are often ignored.

Pipes in series: Continuity shows that the flow through

each pipe is the same, the total head loss is the sum of the head loss

in each pipe. See page 338.

Pipes in parallel: Continuity shows that the

flow through the system is the sum of the flows in the individual pipes.

The head loss to get from point 1 to point 2, through any of the pipes,

is the same, therefore the head loss of each pipe is the same, see page

341.

Back to Table of Contents

Back to Fluid Mechanics' home page

qwertyuiopasdfghjklzxcvbnmQWERTYUIOPASDFGHJKLZXCVBNM

qwertyuiopasdfghjklzxcvbnmQWERTYUIOPASDFGHJKLZXCVBNM

, for turbulent flow

, for turbulent flow