Research Interest

- Functional materials, nanomaterials, and polymer composites

- Sensors (physical, chemical, and biological sensors) and sensor materials

- Micro-/nano-electronics and semiconductor devices

- Micro/nanoelectromechanical systems (MEMS/NEMS)

- Fabrication technology at micro- and nano-scales

- Integration of sensors, electronics, and biomaterials

- Wearable and flexible electronics

|

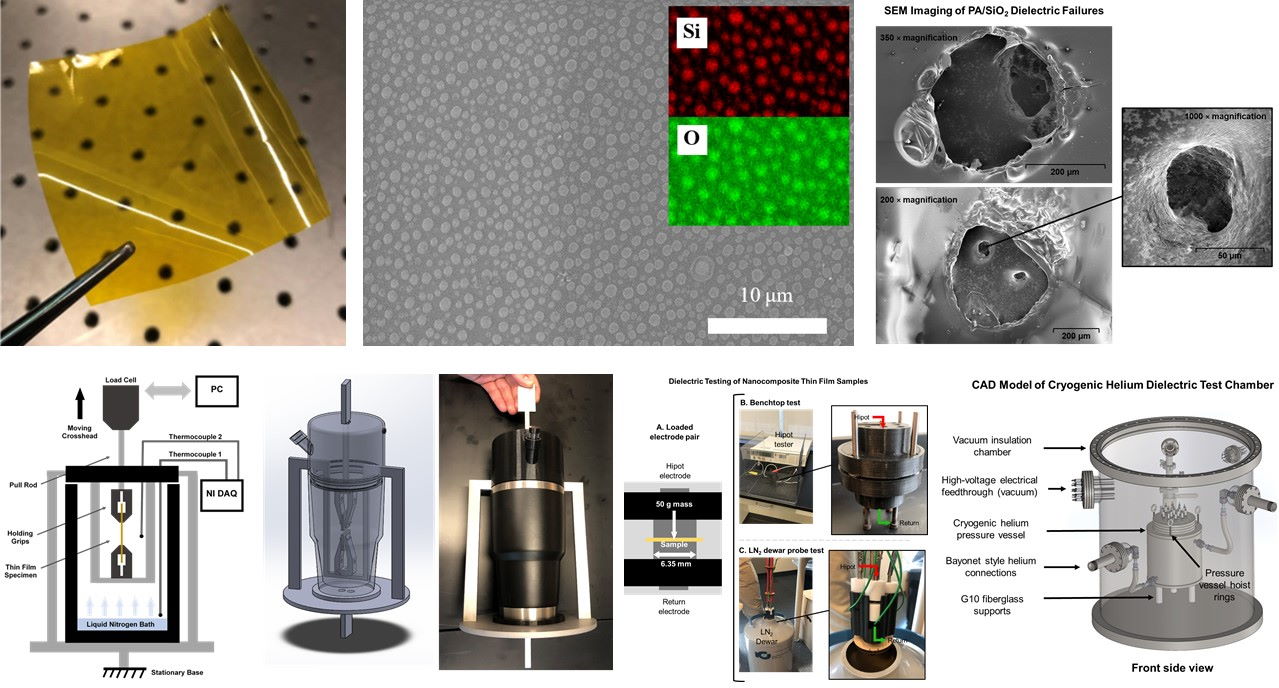

| Current Project: Polymer-Nanoparticle Composites as Cryogenic Dielectrics |

Polymer-based nanocomposites have attracted a lot of attention

lately, due to their enhanced or modified properties from the host

polymers. Our team is investigating nanoparticle-enhanced polymers, as

nanocomposites, for various applications. One particular area we are

exploring is polymer/nanoparticle dielectrics. Adding nanoparticles to

polymers not only can potentially strengthen their dielectric strength,

but also can introduce other interesting features such as optimized

chemical, mechanical, and thermal properties to the final material.

(Collaborator: Dr. Robert Krchnavek, Dr. Lei Yu, Dr. Behrad Koohbor) |

|

|

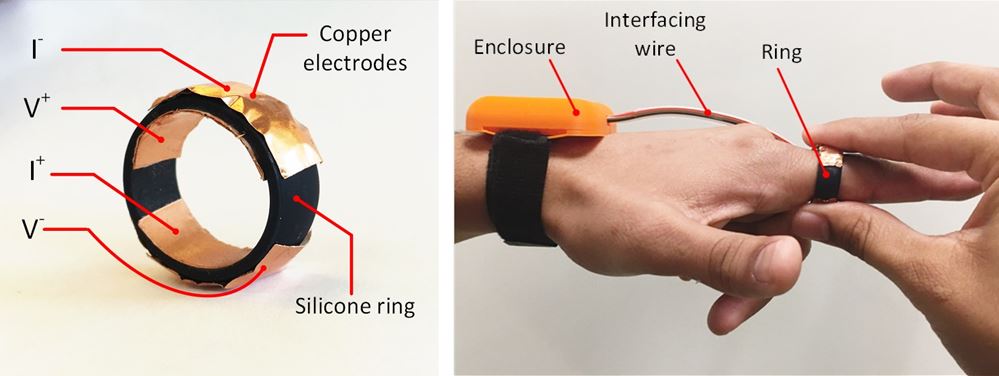

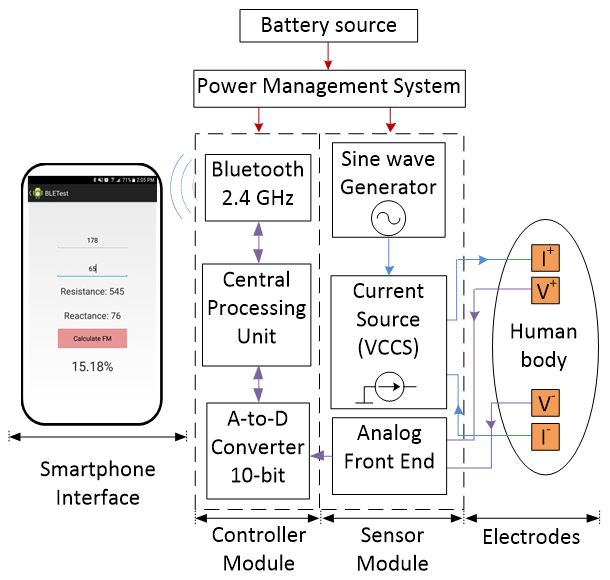

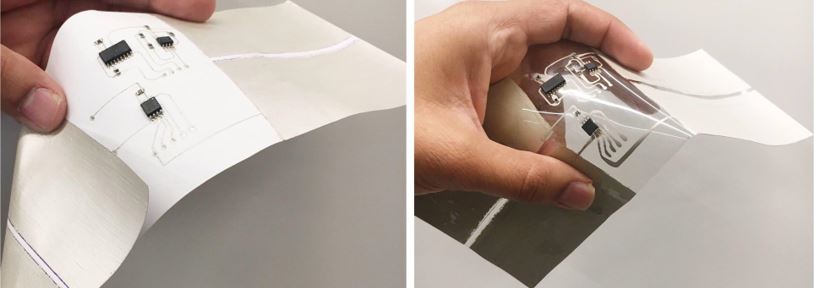

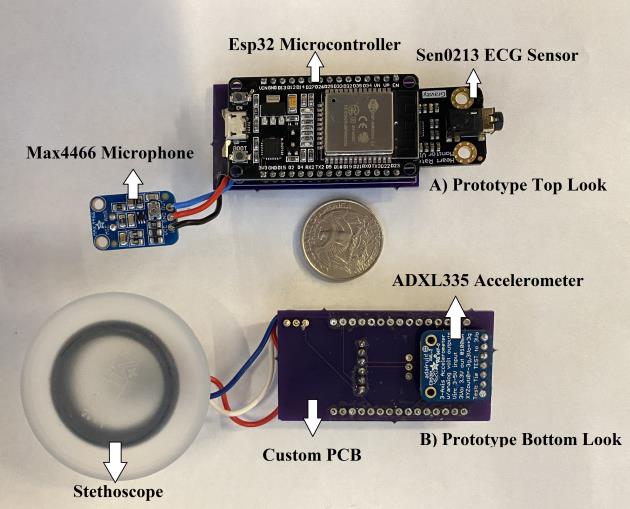

| Current Project: Wearable Electronics and Systems | Wearable

electronics is a potential game changer for healthcare; it can

drastically transform the way patients are diagnosed and treated. We

aim to research and develop wearable systems that combine the

state-of-the-art sensor technology, modern electronics, and

biomaterials. Our objective is to create devices that are light weight,

highly flexible, and comfortable to wear. A key aspect we are exploring

is the integration of MEMS sensors into flexible, biocompatible

materials such as silk or protein materials.

(Collaborators:

Dr. Robert Hirsh, Dr. F. Mac Haas, Dr. Jeffrey

Hettinger, Dr. Adarsh Gupta, Dr. Thomas Merrill) |

|

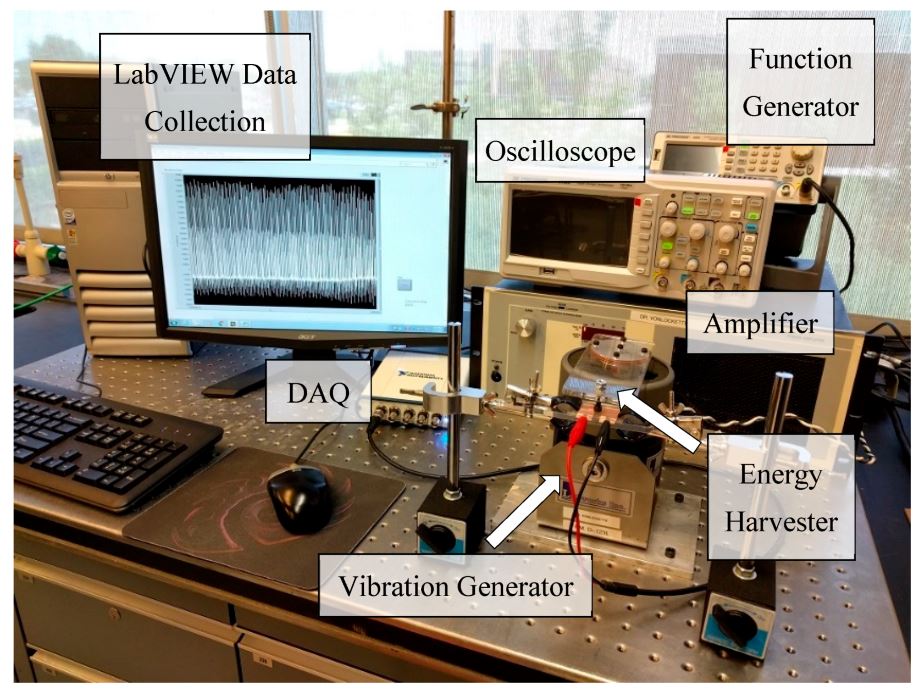

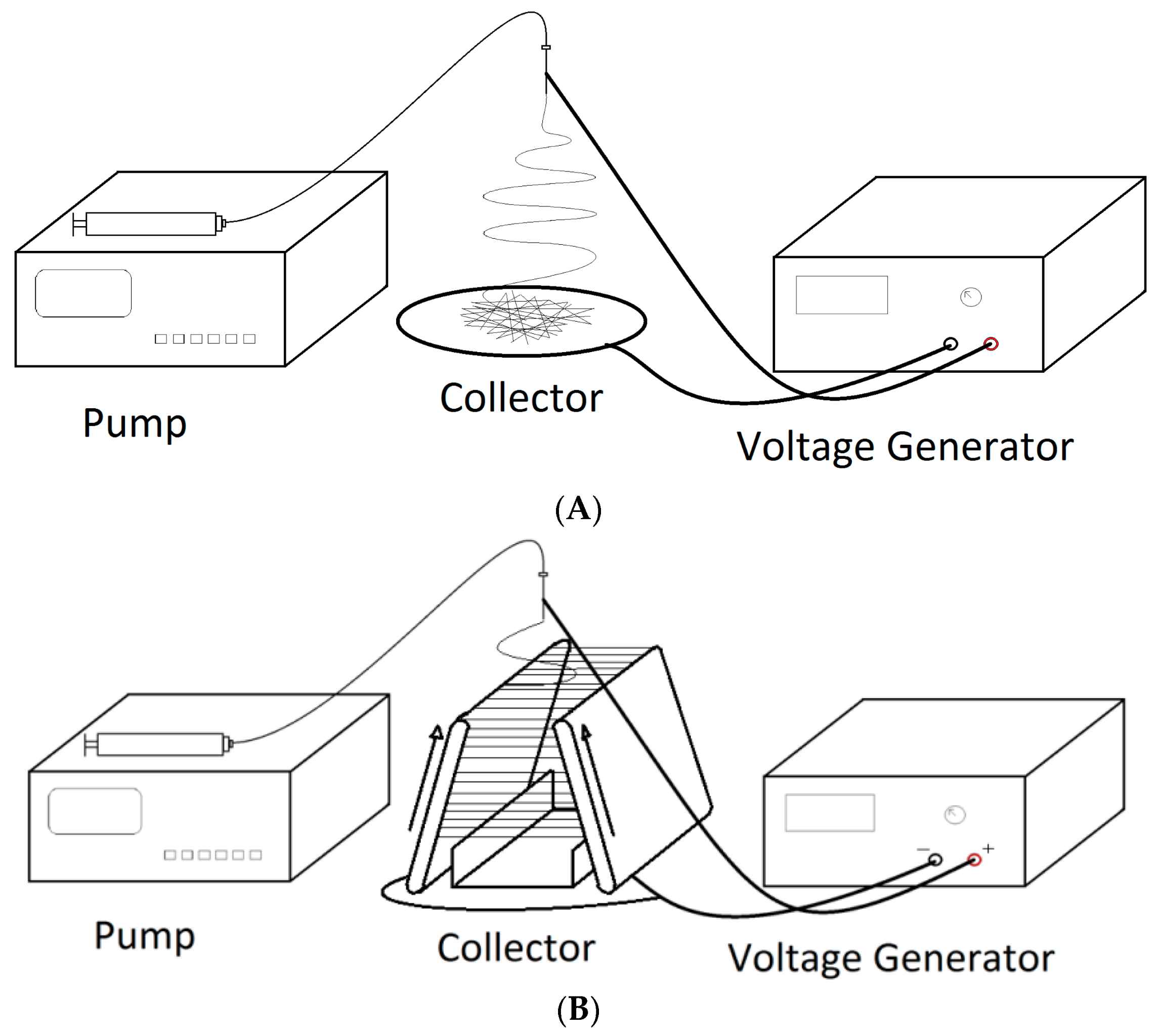

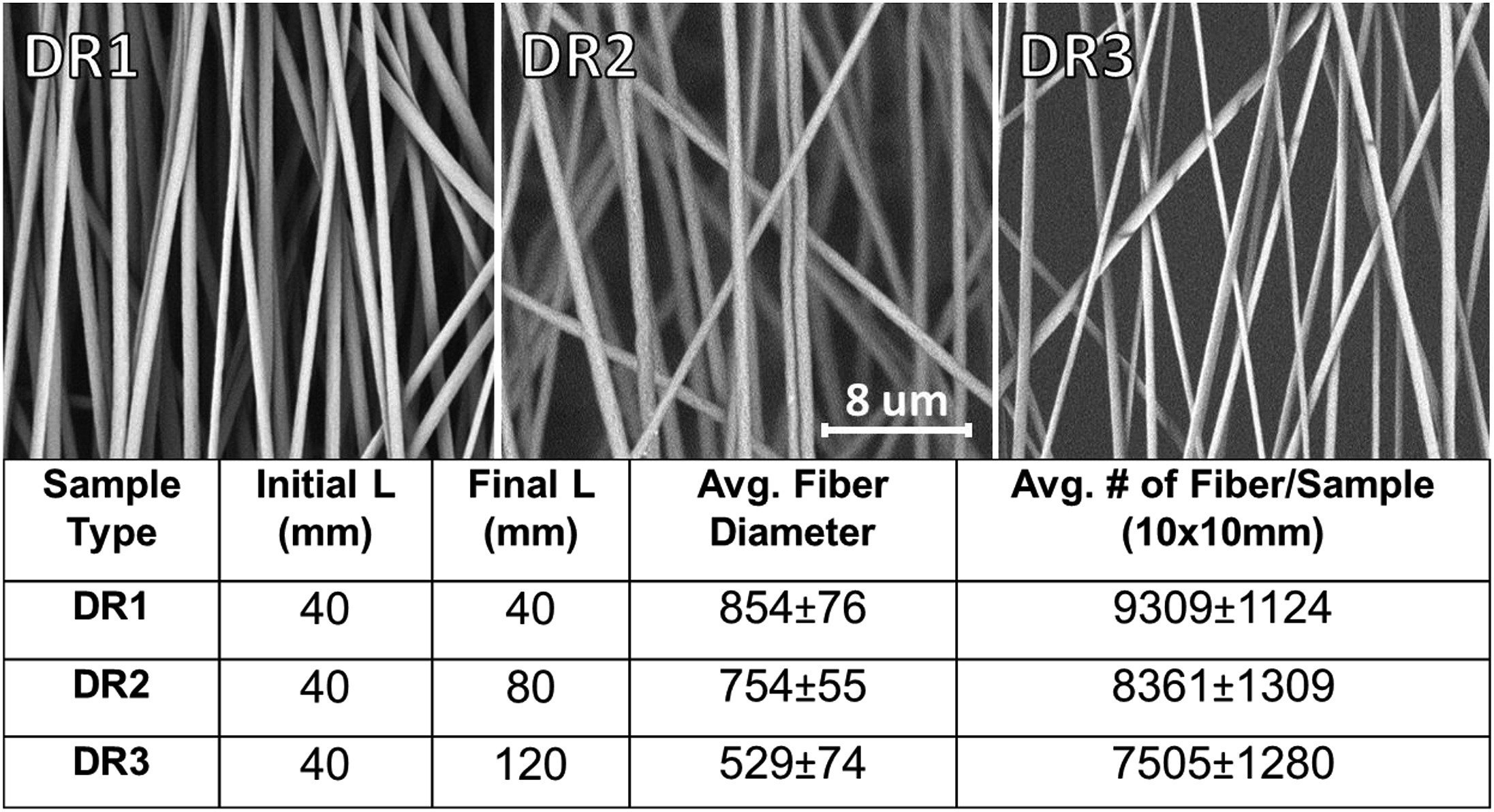

| | Current Project: Nanomaterial-enabled Energy Harvesters | An

average human body produces a large amount of energy throughout the

day. Energy harvested from human body movement such as footfalls and

arm swings can produce continuous, stable energy to portable

electronics and implanted medical devices. For these applications, the

energy harvesters need to be light, small, inexpensive, and highly

portable. We are investigating novel wearable energy harvesters that

can be curved to human skin for electricity generation. One approach is

to integrate polyvinylidene fluoride (PVDF) nanofibers with

flexible substrates; the other one is to combine piezoelectric

nanoparticles into a host polymer. In the long run, these new devices

can continuously harvest vibrational energy from heartbeat or muscle

contraction for electrical use. This research targets the market of

healthcare systems. It will have tremendous impact on implanted medical

devices and the overall healthcare market.

(Collaborator: Dr. Vince Beachley and Dr. Xiao Hu) |

|

| | Previous Project: Superhydrophobicity and Hydrophilicity Enabled by Micro/Nanotechnology | | Inspired

by the “lotus leaf effect” and its related biological structures, the

research on superhydrophobic surfaces has attracted tremendous

attention in the past decade. Many surfaces in nature exhibit

superhydrophobic behaviors with contact angles greater than 150

degrees. Such surfaces typically possess unique properties. Because

many of these surfaces have well-arranged micro/nano-structures, the

creation of these surfaces can be achieved through

micro/nano-fabrication methods. The superhydrophobic surfaces are

finding applications in a wide range of areas, e.g. water-repellent

coatings, self-cleaning fabrics, and anti-icing films. We have applied

different methods to change the surface hydrophobicity of various

materials, resulting in surfaces with a wide range of wettability: from

superhydrophobic to superhydrophilic. | Pillar array to change the wettability of solid materials. The water contact angles range from 170 to 10 degrees |

| | Previous Project: Microfluidic Devices with Integrated Carbon Nanotube (CNT) Sensor Arrays | | The

innovations in microfluidics and microfluidic devices have given sensor

technology new meaning and new opportunities. For example, a

microfluidic exchange system superimposed on a sensor can actively

transport target analytes to the sensor surface, enabling the detection

of analytes at ultra-low concentrations. In our group, we investigate

the effective integration of nanomaterials, electronics and

nanosensors, and microfluidic structures into a lab-on-a-chip device.

The integrated lab-on-a-chip device is designed as a sensing platform

which has great potential for future expansion in various applications.

To create the sensors, we examine the selective deposition of

single-walled carbon nanotubes (SWNTs) with dielectrophoresis to obtain

aligned nanotubes in the forms of thin films, small bundles, and

individual nanotubes. These different results are achieved by changing

a number of parameters in the dielectrophoresis process and the SWNT

samples. The fabrication process is compatible with the traditional

microfabrication technology and has a high potential to be used in the

wafer-level fabrication in the future. | Lab-on-a-chip microfluidic system

conceptual design Microfluidic device with integrated CNT sensors

Aligned individual CNTs

Aligned CNTs between electrodes

Aligned graphene between

electrodes |

| | Previous Project: Carbon Nanotube Electronics and Sensors | | We

have used carbon nanotubes to create electronic devices such as

resistors, field-effectors, and digital logic devices on various

substrates. The high mobility of carbon nanotube enables the

development of faster electronic devices. These devices can also be

used for sensors, especially chemical and bio-sensors, based on their

high surface-to-volume ratio. They demonstrate higher performance

compared with their counterparts made on silicon or other nanomaterials. |

Surface profile of a CNT field-effect transistor (FET)

Enzyme biosensor

using ion-sensitive FET (ISFET)

CNT

digital inverters

CNT

electronic devices on plastic

CNT biosensors on plastic

CNT FET structures and

materials

Testing diagram for CNT ISFET biosensors |

| | Previous Project: Novel Micro/Nano Fabrication Methods | | We

are interested in all kinds of micro/nano fabrication methods and how

these methods can be integrated into one process flow to fabricate

devices. In the past, we have explored various approaches for both

top-down and bottom-up fabrication processes, including hot embossing,

layer-by-layer self-assembly, electron-beam lithography, and

dielectrophoresis. We have also explored various methods for substrate

bonding and device assembly. |

| | Previous Project: Physical Sensors and Actuators on Polymers | | We

have used polymer materials (PMMA) to make physical MEMS devices,

including all-polymer actuators, accelerometers, and tunning magnetic

sensors. Novel fabrication methods such as hot embossing are used to

produce polymer structures at the microscale. We have developed the

expertise of theoretical analysis, modeling (by ANSYS and MATLAB),

fabrication, and device testing of mechanical sensors. (Advisor: Dr.

Tianhong Cui; Collaborators: Dr. Jing Wang, Dr. Yongjun Zhao) | Design of a comb drive for an accelerometer

Fabricated polymer

comb drive accelerometer

Tunneling

tip on polymer

Polymer magnetic sensor

Journal cover

paper |

|

|